Guest blogger, John Howes, is the founder of Redland Energy Group where he has been a senior strategic advisor on energy policy and natural resources for nearly three decades.

New Biden Administration Requests More R&D Investment in Battery Technology

The recent Energy Storage Grand Challenge Market Report for 2020 from the U.S. Department of Energy (DOE) includes a chapter on lead batteries and their role in the future of energy storage. It reflects growing recognition from DOE and others that lead batteries are among important energy storage technologies that require investment to secure America’s global leadership on technological innovation and a green economy infrastructure. It is a dramatic shift from the 2017 report in which lead batteries had only a two-paragraph mention.

The Energy Storage Grand Challenge (ESGC) launched last year has received bipartisan funding support from Congress to continue and expand under President Joe Biden. In addition, included in the Biden Build Back Better Recovery Plan is a call to invest deeply in battery technologies to secure America’s global energy leadership.

A Sustainable, Ready-to-Scale Battery Technology Gains New Recognition.

For more than 100 years, the lead battery has been the world’s most well-established and best-selling rechargeable battery. Last year, lead batteries accounted for more than 70 % of worldwide sales in the global $90 billion battery market. The lead battery industry in North America has long held the title of the most recycled consumer product and remains a strong domestic manufacturing sector. Until recently, that longevity might have created the perception among scientists in industry and government that lead batteries are old and ready to be displaced by other battery chemistries.

That point of view is no longer valid as in just three short years, DOE has recognized that what scientists may have considered old is now becoming new again. The DOE December 2020 report, “2020 Grid Energy Storage Technology Cost and Performance Assessment,” includes lead batteries among seven storage technologies receiving high profile attention:

- Lithium-ion: lithium-ion iron phosphate (LFP) batteries

- Lithium-ion: lithium-ion nickel manganese cobalt (NMC) batteries

- Lead-acid batteries (PbA)

- Vanadium redox flow batteries (RFBs)

- Compressed-air energy storage (CAES)

- Pumped storage hydro (PSH)

- Hydrogen energy storage system (HESS) (bidirectional)

Viewing Lead Batteries Through a New Lens.

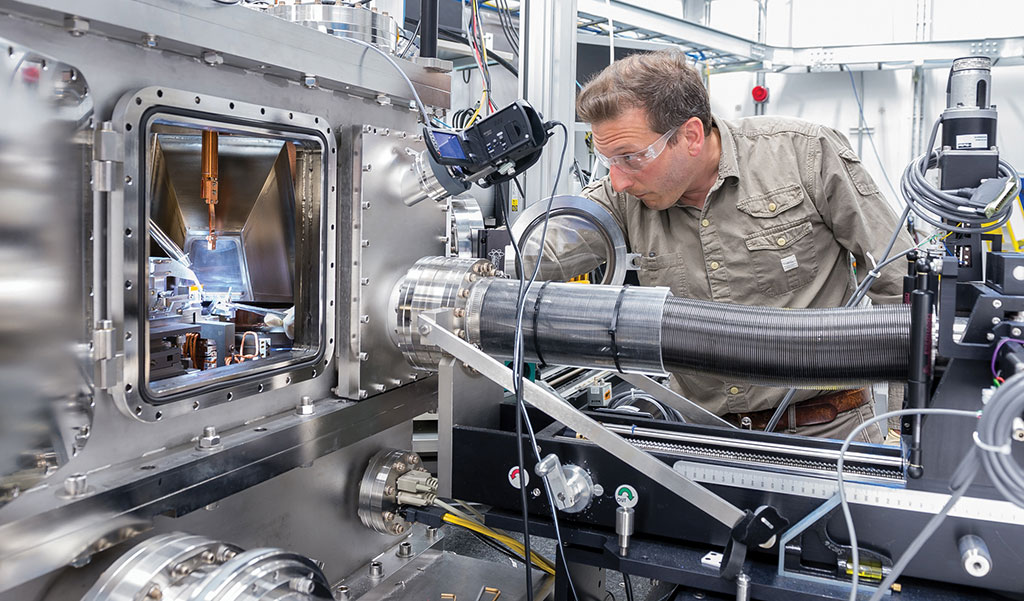

The new report is a much deeper dive into the material science of lead batteries compared to how DOE viewed them in 2017. This is consistent with another 2020 DOE activity, the Office of Electricity’s Peer Review, which featured recent work of Pacific Northwest National Laboratory and Argonne National Laboratory on electrolyte and its effect on lead battery performance.

Certainly, much of DOE’s energy storage research will remain focused on lithium batteries. But DOE is broadening its R&D activities into other energy storage technologies so consumers can have a wide array of energy storage options. (Under the FY21 omnibus appropriations bill enacted last month, DOE is required to file quarterly reports to Congress on the progress of its Energy Storage Grand Challenge program.) Scientists in national laboratories say their job is not to pick winners and losers. Rather, they use their state-of-the-art equipment to help industries develop the best possible products and leave purchasing decisions to consumers.

Scientists Now Recognize the Untapped Potential of Lead Batteries.

Why is DOE paying more attention to lead batteries? Is it because the industry has a strong domestic manufacturing base? Is it the industry’s strong safety record or the lead battery’s unequaled 99% recycling rate? Those are important considerations and scientists are fully aware of them. But what has really captured DOE’s attention is the realization that only half the energy potential of a lead battery is being used, a major reason why batteries don’t last as long as they could. Scientists are asking about the other half and want to learn if a deep dive into material science helps improve the performance of a product that already is safe, sustainable and manufactured in North America.

Battery Industry Accepts the Challenge.

If 2017 was the year DOE had only two paragraphs in its energy storage report, it also was the year that 14 companies in the North American lead battery industry formed the Lead Battery Science Research Program (LBSRP) and entered a Cooperative Research and Development Agreement (CRADA) with DOE’s Argonne National Laboratory to use the lab’s state-of-the-art equipment and expertise to examine materials in a way that has never been done before. That CRADA now is in its third year with 15 members and is receiving increased participation not only from industry trade groups like Battery Council International (BCI) and the Consortium for Battery Innovation (CBI), but other national laboratories. Even scientific journals are taking notice.

Science Magazine in August 2020, published, “Past, present, and future of lead–acid batteries,” which stated, “Perhaps the best prospect for the unutilized potential of lead–acid batteries is electric grid storage, for which the future market is estimated to be on the order of trillions of dollars. For that reason, the low cost of production and materials, reduced concerns about battery weight, raw material abundance, recyclability, and ease of manufacturing make it an attractive solution if technical barriers can be addressed.”

Gaining Better Knowledge to Improve Batteries.

Over the past three years, Argonne scientists have met regularly with LBSRP member companies to identify a range of specific topics. The 2020 DOE report reflects some of those discussions including:

-

- How to improve cycle life for valve-regulated cells/modules at high DOD (depth of discharge)

- The need to identify a grid alloy that promotes further oxidation of highly resistive PbO (lead oxide) without increasing self-discharge

- Gain better understanding of the mechanism of role of expander on negative active material performance

- How to increase DOD such that rated capacity is based on higher DOD than the current ~ 50% DOD

- The need to design cells to fit the grid service by proper choice of electrolyte, positive and negative utilization, and grid composition

- The replacement of the negative grid (in the battery) with copper improves battery performance

- Importance of a standardized formation procedure conducive to intended grid service

- Addressing electrolyte stratification with nonintrusive ways to circulate the electrolyte

- Baffles

- Reverse pulses

- Micro pumps

- The need to find a suitable substitute for Sb (antimony) at the positive grid (in the battery) to avoid highly resistive PbO layer that promotes interparticle conductive among PbO active material particles

- Improved stability of expanders at higher temperature mitigates degradation at high temperatures

- Better understanding that the mechanism of additives to electrolytes increases battery life

Other topics are likely to emerge as the lead battery industry’s work with DOE and the national laboratories continues.

The Goal: To Dramatically Improve Battery Performance and Lower Costs.

The goal of this research is to increase the performance potential of lead batteries from their current 50%. Why is that important? The 2020 DOE report says that while pumped hydro storage and compressed air storage are favored among utility system operators, they can only be installed at specific locations: large bodies of water in the case of pumped hydro and large underground caverns in the case of compressed air. Batteries, however, can be placed anywhere. The DOE report says lithium-ion, vanadium redox flow and lead batteries can become attractive storage options for integrating renewable resources to the electric power system if their costs can approach pumped hydro and compressed air.

The need to bring down the cost of batteries is particularly urgent as utilities face the challenge of integrating variable power from renewable wind and solar sources to their systems.

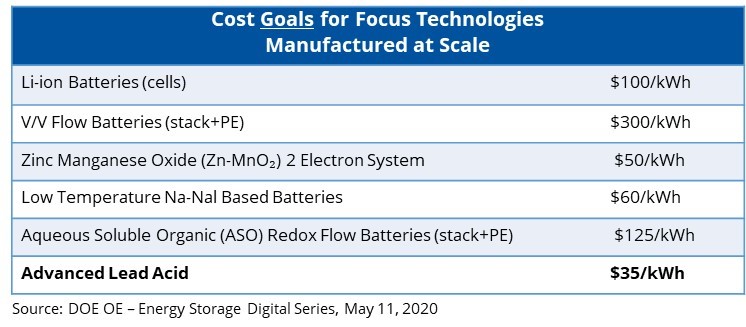

The DOE’s Office of Electricity (OE), which manages energy storage research for electric power system applications, has identified potential cost targets for various battery technologies. Its target for lead batteries is particularly ambitious and the underutilized potential of today’s batteries is the basis for this ambitious cost reduction goal.

Can the lead battery industry reach the $35/kWh goal? The answer lies in how successful scientists from industry, national laboratories and other academic institutions can be in working together to confront those challenges. The fact that the new DOE report gives such prominent attention to lead batteries is an important step in the right direction for an old but new industry.