In this series, we’re touring – and sharing profiles on – several U.S.-based manufacturing “stars.” All are BCI member companies who provide innovative lead batteries, and the services and supplies used to make those batteries. Collectively, these companies are the backbone of a vast domestic infrastructure that is ensuring a reliable source of sustainable energy to power the U.S. economy.

“We Make, We Innovate” Best Describes Innovative, Indiana-Based Manufacturer

If you were going to pick a phrase to describe what Hammond Group does, it would be “We make and innovate,” said Terry Murphy, its president and CEO. That’s fitting for a company whose tagline is The Change Catalyst.

Hammond Group, Inc., is a chemical manufacturer headquartered in Hammond, Indiana, and operating in the Americas, Europe and Asia. Its primary business is supplying the lead battery market with oxides and specialty performance additives that improve a battery’s performance.

The company also is propelling research to advance energy storage solutions for the automotive, industrial, telecommunications and renewable energy markets. According to Murphy, Hammond’s work is making a notable impact, far beyond the Hoosier state.

“Our products are contributing to the battery industry’s leadership in the world’s transition to new, environmentally friendly energy storage.”

Internally, Hammond has developed manufacturing and processing efficiencies to reduce energy consumption and increase sustainability. That includes producing materials at twice the industry average, while maintaining strict quality standards.

Watch this short video on who Hammond is and the important, innovative work they’re doing in the lead battery industry space.

For its customers, Hammond has developed performance additives including SureCure® and GravityGuardTM that enable reduced energy use in the manufacturing process and increased battery performance and product life.

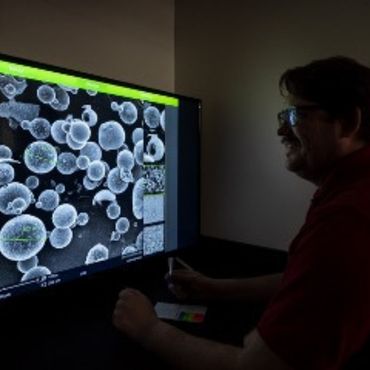

Modern Research Facility Drives Innovation, New Products

Hammond champions the idea that lead batteries will be key to a sustainable future. In 2016, the forward-thinking company built a state-of-the-art research facility, called E=(LAB)2, at its Indiana headquarters to drive lead battery innovation.

The center offers structured programs in materials research, cell manufacture, battery testing, and provides customized solutions for traditional and next generation batteries. It has since become a leading research center.

“We partner with the Consortium for Battery Innovation, Purdue University, Bulgarian Academy of Sciences, Argonne National Laboratory, and others to drive innovation,” said Murphy. It has resulted in Hammond being awarded the Battery Council International Innovation Award twice in the past five years. This past summer, the work of E=(LAB)2 also warranted a visit from Indiana State Representative Mike Andrade.

Hammond’s Economic Impact: Boosting Indiana’s Bottom Line

At its two Indiana manufacturing plants, Hammond processes over 250 million pounds per year of various specialty material additives for use in lead battery applications, from automotive to industrial. The economic impact reverberates, especially throughout Indiana:

- Hammond purchases recycled lead from the Indiana facilities of other U.S.-based BCI member companies.

- Hammond sells battery oxide and performance products to customers across North America.

- Hammond’s three Indiana facilities source a myriad of goods and services from local suppliers. In 2021, total purchases from Indiana suppliers exceeded tens of millions of dollars.

- Hammond employs over 125 full-time employees in Northwest Indiana and Pottstown, Pennsylvania.

Employee Owned, with a Tradition Serving Generations

As a company with a 92-year history, it’s not unusual to encounter third- and fourth-generation employees in its current workforce. In 2019, Hammond became an Employee Stock Ownership Plan (ESOP) company to enable employee ownership.

“By operating as a team of employee-owners, our company fosters a culture that is good for workers, good for business, and good for the community and the customers we serve,” Murphy added. “We believe that when employees own the company, they will be excellent stewards of its prosperity and work hard to make it better.”

Thank you, Hammond Group, for letting us get to know you better!

Watch this space, as we travel the country (virtually and in-person), sharing more about an essential industry that provides 60% of the world’s rechargeable energy storage and contributes billions to the U.S. economy.