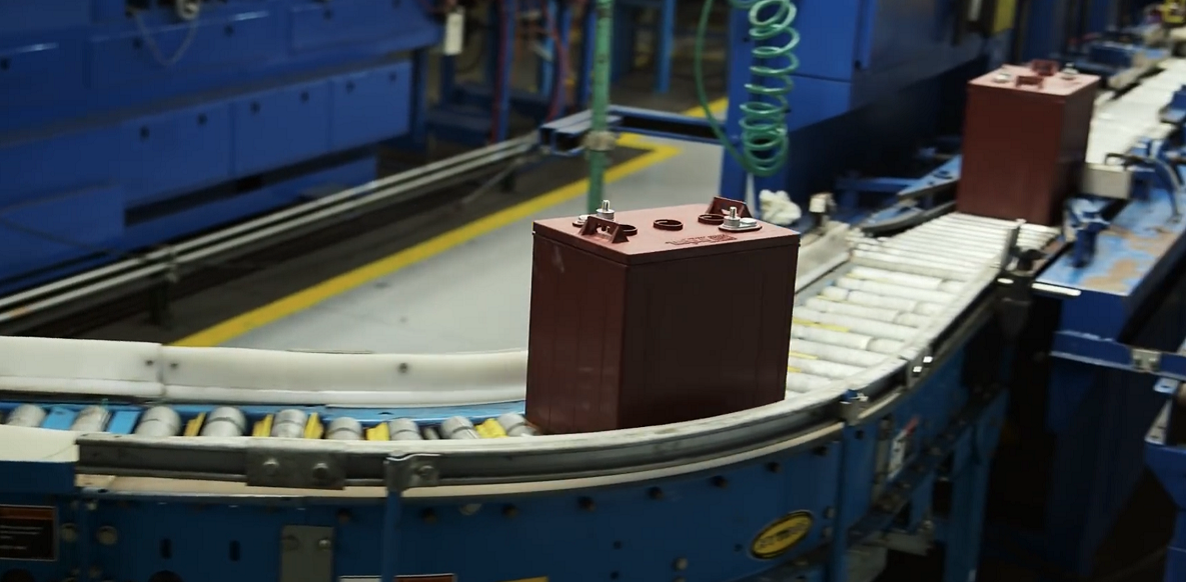

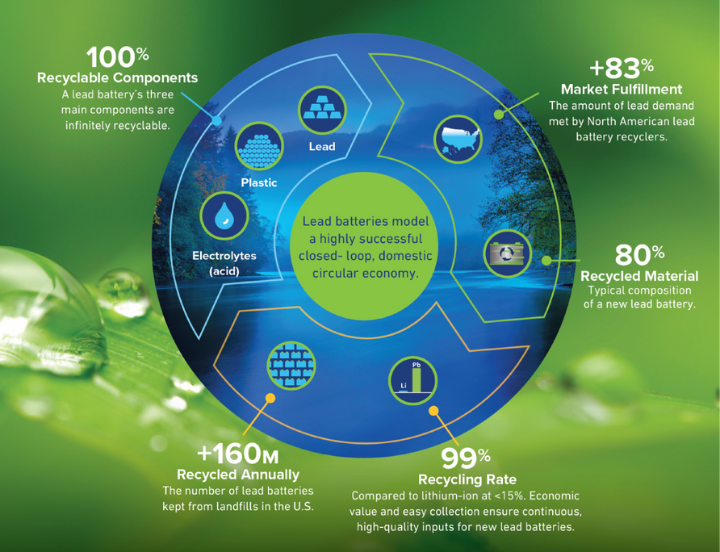

Global events have created foreign supply chain disruptions and increased threats to our country’s security, safety, economy and clean energy goals. Yet lead batteries continue to withstand the world’s greatest crises. The industry’s vast North American infrastructure and proven circular model ensure it can help meet the demand for critical and clean energy storage.